3D Printing with Forth

Part I

November 20, 2021

FORTH DAY!

Overview

- Intro to 3D Printing

- G-code and printer control

- Constructive Solid Geometry

- Signed Distance Fields

- Deciding the Path

- Fixing my microwave

Reprap

- Adrian Bowyer, University of Bath 2005

- Open-source 3D Printer that can print itself

https://reprap.org/wiki/RepRap

Prussa i3 (2012, kit 2015)

https://reprap.org/wiki/RepRap

- Rectilinear Printer

- Moving Heated Bed

- Moving Extruder Motor

Kossel (2012)

https://reprap.org/wiki/RepRap

- Delta Printer

- Stationary Glass Bed

- Stationary Motors

My FLSUN Kossel

- Kit Version of Kossel

- Added Metal Heated Bed

- ~$200 in 2017

My FLSUN Kossel

- Kit Version of Kossel

- Added Metal Heated Bed

- ~$200 in 2017

My FLSUN Kossel

- Kit Version of Kossel

- Added Metal Heated Bed

- ~$200 in 2017

My FLSUN Kossel

- Kit Version of Kossel

- Added Metal Heated Bed

- ~$200 in 2017

My FLSUN Kossel

- First control board weird

- FLSUN good about replacing

Materials

- PLA - Polylatic Acid

- Polyester made from corn, cassava, sugarcane, or sugar beet pulp.

- Used for recyclable utensils.

- Melts at ~155°C (~311°F).

- ABS - Acrylonitrile butadiene styrene

- Mixed terpolymer made from natural gas and petroleum.

- Used for Legos.

- Melts at ~200°C (392°F).

Filament Spool

Filament Spool

ATMEGA2560

- 54 Digital I/O Pins (12-15 can do PWM)

- 16 Analog Input Pins

- 5V, 256KB Flash, 8KB SRAM, 4KB EEPROM

Control Board

Marlin Fireware

- Open-source G-code control software

- Over 150 commands

- Tethered or SDcard operation

G-code

- Computer Numerical Control (CNC) Language

- Appeared 1950! Standardized in 1980 - RS-274

- Single letter codes to control:

- X, Y, Z position/movement

- Filament extrusion

- Extruder and bed temperature

- Rebasing / speed

G-code Example

M107 ; fan off

M190 S60 ; set bed temperature to 60

M104 S200 ; set temperature to 200

G28 ; home all axes

G1 F5000 ; set speed 5000mm/min

G1 X0.000 Y0.000 Z5.000

M109 S200 ; wait for temperature 200

M21 ; set units to millimeters

G90 ; use absolute coordinates

M82 ; use absolute distances for extrusion

G92 E0 ; set zero position (E=extruder)

G1 F9000 ; set speed 9000mm/min

G1 X0.000 Y0.000 Z0.300

G-code Example

G1 X-11.600 Y-9.800 E0.009

G1 X-11.300 Y-9.800 E0.018

G1 X-11.000 Y-9.800 E0.027

G1 X-10.700 Y-9.800 E0.036

G1 X-10.400 Y-9.800 E0.045

G1 X-10.100 Y-9.800 E0.054

G1 X-9.800 Y-9.800 E0.063

G1 X-9.500 Y-9.800 E0.072

G1 X-9.200 Y-9.800 E0.081

G1 X-8.900 Y-9.800 E0.090

G1 X-8.600 Y-9.800 E0.099

G1 X-8.300 Y-9.800 E0.108

G1 X-8.000 Y-9.800 E0.117

G1 X-7.700 Y-9.800 E0.126

G1 X-7.400 Y-9.800 E0.135

Movement & Extrusion

G1 ; Linearly interpolate (E.g. G0 goes straight there)

X0.000 ; X coordinate

Y0.000 ; Y coordinate

Z5.000 ; Z coordinate

E0.3 ; Extrusion position

Describing 3D Models

- Platonic Solids

- Triangle Meshes

- Non-Uniform Rational B-Splines

- Voxels

- Constructive Solid Geometry

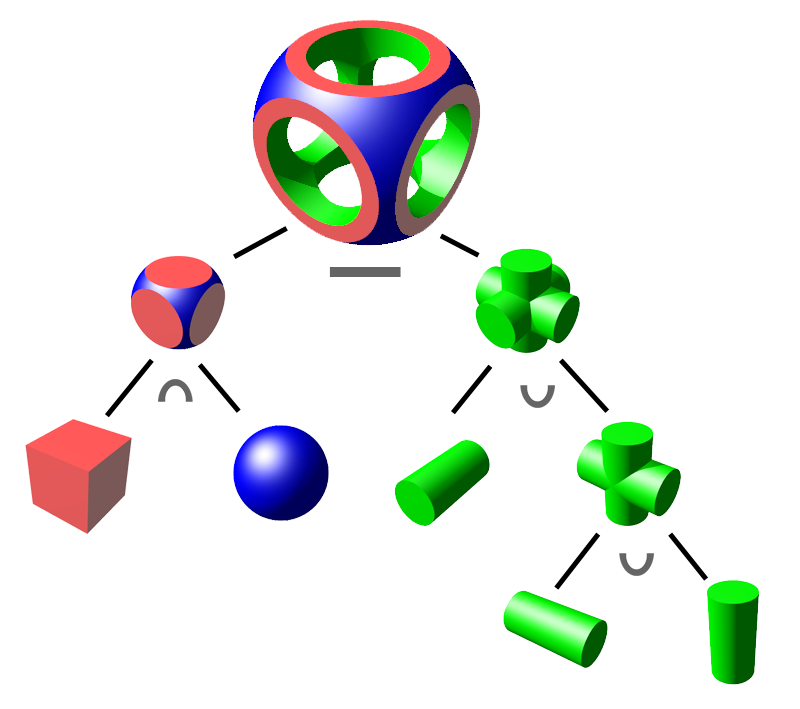

Constructive Solid Geometry

https://en.wikipedia.org/wiki/Constructive_solid_geometry#/media/File:Csg_tree.png

: model

gpush

6 mm -7500 um 1500 um - 1 mm translate

4 mm 3 mm 1 mm prism

gpop

gpush

0 7500 um 10 mm - 5 mm translate

5 mm 3500 um cylinder

gpop

difference

;

Units

: um ;

: mm 1000 * ;

: cm 10 mm * ;

: signoformat ( n -- n d ) s>d swap over dabs ;

: n. ( n -- ) signoformat <# #s rot sign #> type ;

: mm. ( n -- ) signoformat

<# # # # [char] . hold #s rot sign #> type ;

Printer Head

- Track position

- Extrusion and flow rate

variable x variable y variable z variable e

variable flow 30 flow !

Signed Distance Fields

- Function mapping position to signed distance from the surface of an object

- For example a sphere: \[ S(x,y,z) = \sqrt{x^2+y^2+z^2} - r \]

Sphere / Cylinder

: sphere ( r -- n ) x @ square y @ square + z @ square + sqrt swap - ;

: cylinder ( h r -- n )

x @ square y @ square + sqrt swap - swap z @ abs swap - max ;

Rectangular Prism

: prism ( x y z -- n )

z @ abs swap - swap y @ abs swap - max swap x @ abs swap - max ;

Union

: union ( a b -- n ) min ;

Intersection

: intersection ( a b -- n ) max ;

Inverse

: inverse ( n -- n ) negate ;

Difference

: difference ( a b -- n ) inverse intersection ;

Transforms

: translate ( x y z -- ) z -! y -! x -! ;

: scale ( x y z -- )

z @ swap 1000 */ z !

y @ swap 1000 */ y !

x @ swap 1000 */ x ! ;

: uscale ( s -- ) dup dup scale ;

Geometry Stack

create geostack 300 cells allot

variable geosp geostack geosp !

: gunipush geosp @ ! cell geosp +! ;

: gunipop cell geosp -! geosp @ @ ;

: gpush x @ gunipush y @ gunipush z @ gunipush ;

: gpop gunipop z ! gunipop y ! gunipop x ! ;

Complex Shapes

Filling Each Layer

- Flood fill each layer

- Alternate horizontal / vertical bias

- Represent x,y as a x+y*slicelength single value

- Emit G-code as you go

Floodfill Stack

create floodstack slicelength 100 * cells allot

variable floodsp floodstack floodsp !

: flooddepth floodsp @ floodstack - cell / ;

: unflooded floodsp @ floodstack <> ;

: floodpush floodsp @ ! cell floodsp +! ;

: floodpop cell floodsp -! floodsp @ @ ;

https://en.wikipedia.org/wiki/Flood_fill#/media/File:Smiley_fill.gif

Floodfill

variable floodorder

: toggleorder floodorder @ invert floodorder ! ;

: horiflood ( pos -- pos )

dup 1- floodpush

dup 1+ floodpush

dup slicelength - floodpush

dup slicelength + floodpush ;

: vertiflood ( pos -- pos )

dup slicelength - floodpush

dup slicelength + floodpush

dup 1- floodpush

dup 1+ floodpush ;

Floodfill

: flooddrain

begin unflooded while

floodpop

dup c@ if

0 over c!

floodorder @ if horiflood else vertiflood then

pointify

2dup dist 500 um > if 9000 speed moveto

600 speed else lineto then

else drop then

repeat

;

Broken Microwave

- Plastic holding spring and latch broke

- Replace the broken piece with a 3D Printed insert

- Iterative design with Forth was faster

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.youtube.com/watch?v=D0VizKQg6pw

https://www.amazon.com/Samsung-SAMSUNG-DE64-00760A-KEY-DOOR/dp/B001GDGHKC/ref=asc_df_B001GDGHKC/

https://www.amazon.com/Samsung-SAMSUNG-DE64-00760A-KEY-DOOR/dp/B001GDGHKC/ref=asc_df_B001GDGHKC/

https://www.amazon.com/Samsung-SAMSUNG-DE64-00760A-KEY-DOOR/dp/B001GDGHKC/ref=asc_df_B001GDGHKC/

https://www.amazon.com/Samsung-SAMSUNG-DE64-00760A-KEY-DOOR/dp/B001GDGHKC/ref=asc_df_B001GDGHKC/

2

2

3

4

4